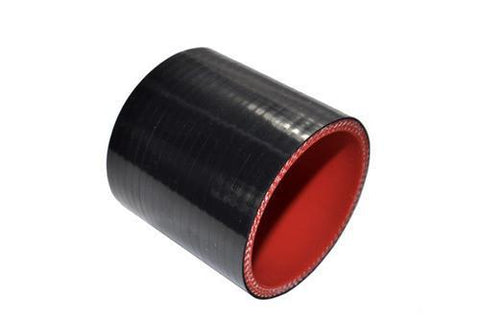

What is silicone coupling?

Silicone couplers (heavy duty pressure connections) prevent liquids and gases from bursting at the connection site, and they can facilitate the flow of chemicals, oil, and water–even when dealing with extreme temperatures. They can be used on intercoolers, superchargers, cold air intakes, and radiators.

MAPerformance carries silicone couplers

For a wide array of silicone couplers, cold air intakes, and boost pipes, there's no better place to buy than at MAPerformance. We carry the highest-quality selection of silicone parts, air intake tube coupler products, stainless steel pipes, and exhaust parts on the internet. Shop from the best aftermarket wide range of tubing coupler inventory, intake pipe products, and silicone hose products at the lowest price on the web, guaranteed thanks to the MAPerformance Price Match Guarantee.

When it comes to high-grade silicone, quality matters. That's why we sell only the best products that enhance both cosmetic and performance aspects of your car.

Buying silicone couplers from MAPerformance, you'll get great perks like fast, free shipping on orders over $199, and a hassle-free 90-day return policy. We care about your part-buying experience as much as you care about your ride.